摘要

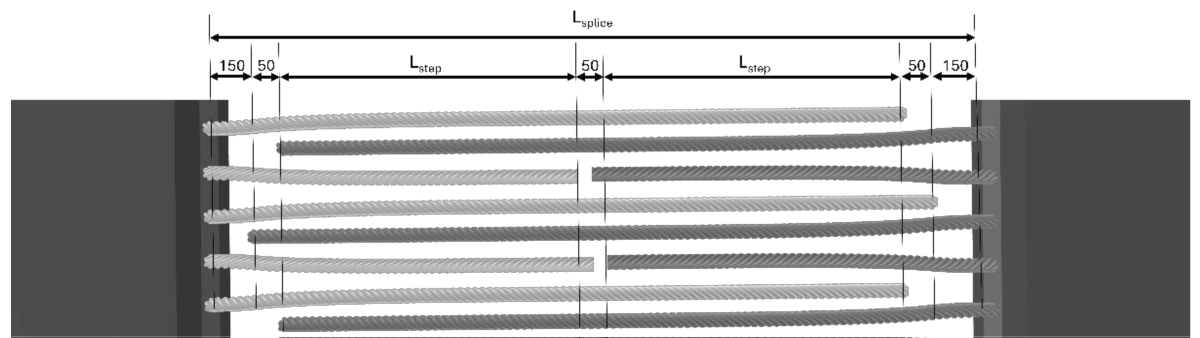

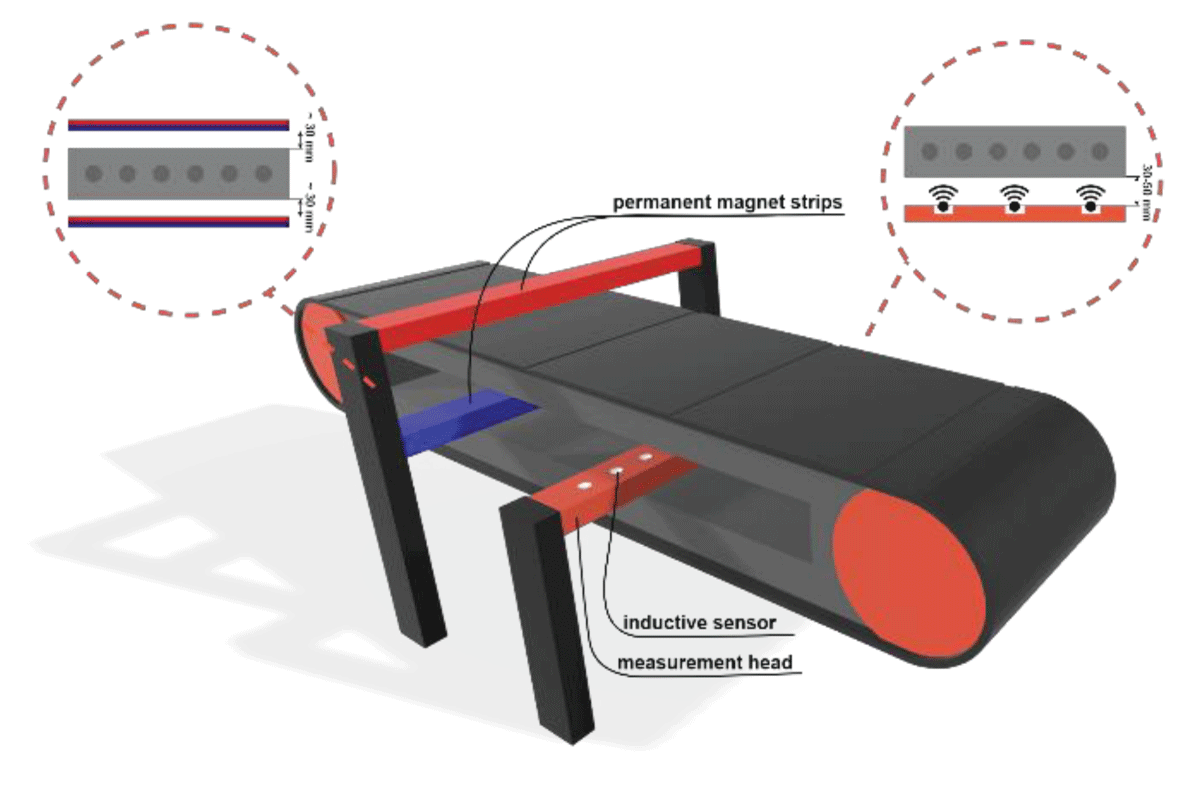

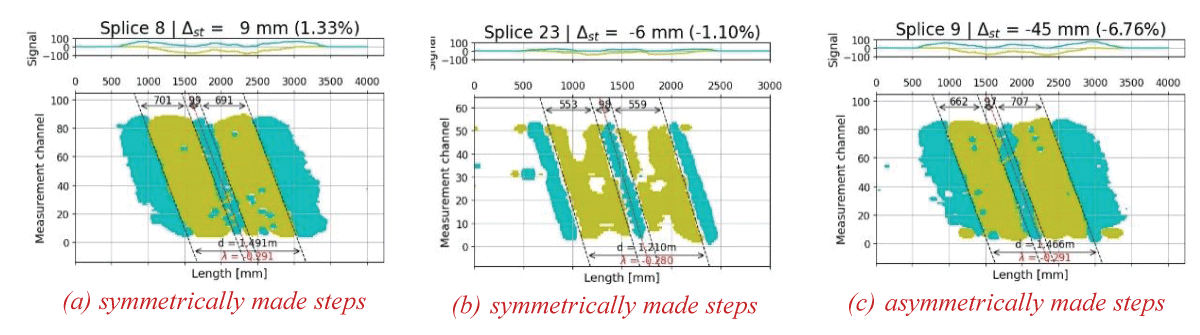

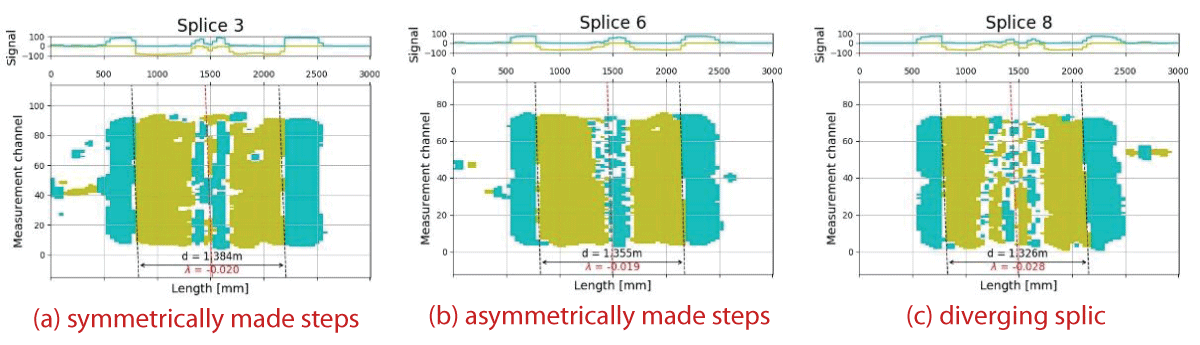

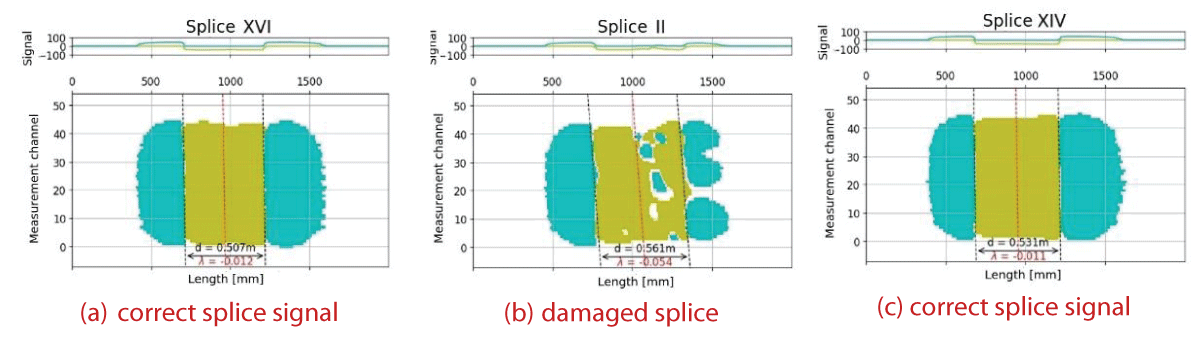

The proper geometry of belt splices influences their subsequent performance and durability during operation. Despite being such a critical aspect, evaluating the geometry of splices can be challenging, especially after their fabrication and vulcanization. This article presents an approach to diagnosing the geometry of belt splices based on the examination of belts using the DiagBelt+ magnetic system. Through the analysis of practical applications and the benefits derived from monitoring splice geometry, the article emphasizes the importance of diagnosing the geometry of belt splices to improve their quality and performance.